255,720 Camper overhaul

The camper was transported back to the VW garage in Assen on 28/4/23 from the harbor in Bremerhaven. For the next 3-month Ben, Roland and xxx worked on the camper to replace the engine with a refurbished engine with 187,593 km on the clock. The opportunity was taken to also replace the turbo which was stuck as well as the glow pugs which caused us so many starting issues along the way.

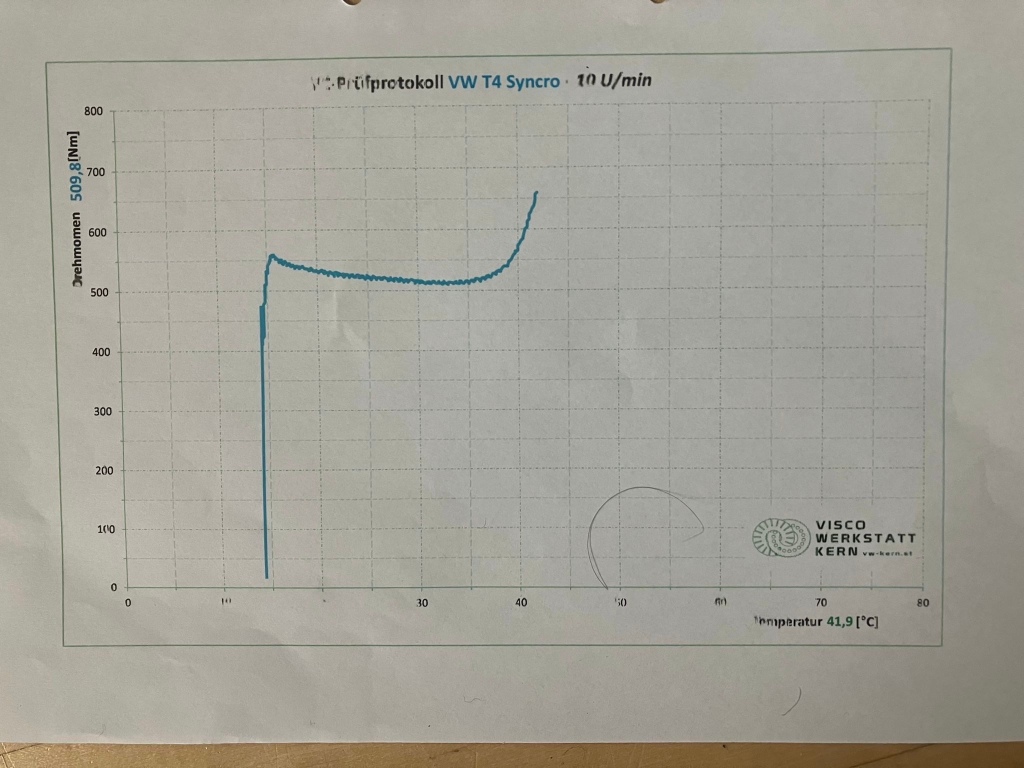

The 4×4 gearbox which came out of the Austrian donor T4 in 2015 and therefore had over 330,000 km on the clock. I had it serviced whereby one of the cone bearings was replaced. The Visco Coupling (syncro) also had the same amount of km on it. I sent it back to Austria (Visco Werkstatt Kern) and replaced it with a refurbished one (sport model with higher torque transmission). When testing the old syncro it immediately locked up. This meant that I had been driving in 4×4 mode for over 10.000 km with a locked driveshaft. Logic that, due to high forces, one of the bolts connecting the axel to the gearbox broke out and the axel started to vibrate. The axel was removed in Fort Nelson (Canada) and, once home, I sent it back to Technotrans in Veendam for an overhaul. One CV joint on the axel and the Hardy schibe (front) were damaged and had to be replaced.

On 11/8 we picked up the camper and made a 3000 km test drive with the camper through Cornwall and Devon in September 2023. It was again a joy to drive. No issues (vibrations) climbing the sometimes 28% hills. We now look forward to some trouble-free camping trips in Europe.

255.720 Driving belt broke resulting in a broken crankshaft. Without much worning the engine power stopped. We made it to the side of the road and looked underneath the bonnet. The cover of the driving belt was shifted. The road service man, we managed to call, confirmed that the belt was broken. They towed the camper back to a VW dealer in the nearby city. It was a long weekend so only on Tuesday did they have a look and removed the various wheels around the driving belt. The main toothed wheel connected to the crankshaft was however loose. Conclusion a broken crankshaft. We arranged a tow truck to bring the camper to the harbour in Veracruz (490 km away!) to put the camper in a container for shipment to Bremerhaven in Germany. To enter the container (2.59 m high inside) The MaxFan had to be removed and the tier pressure dropped. We are now waiting for the camper to arrive.

255.700 Right break pad worn out. Just before closing time I managed to get a mechanic to open up the right front break and replace the worn out break pad with on of the spares I had.

255.234 km Left motor side CV joint While driving up a steep hill the motor side CV joint failed. It first stated to make some noise and then the axle started spinning and we lost power. At te workshop it was discovered that one bolt was broken and as a result the CV joint started to vibrate. A second bolt wobbled out and fell on to the oil pan. The mechanic was able to remove the broken off bolt and replace all bolts with slightly longer ones. The bearings and cage were still OK as well as the rubber cover. It was all put back together again and we could drive on after 1 day in the workshop.

253.722 km Timing belt broken resulting a a damaged dieselpump. Our belts driving the dieselpump suddenly broke when going over one of the many speed pumps in Mexico. When looking at it, it became clear that the wheels which should tighten the belt were coming loose and at one point the belt just wobbled and broke. Apparently this happens more often because of the vibrations caused by the dieselpump (so check the tensioner wheels regularly). I installed a spare belt but the timing was totally off so it had to go to a garage (open air shelter at the top of a narrow road). The workman did a good job adjusting the timing but the engine just would not start. It was suspected that the dieselpump itself was damaged. After a week my dieselpump was repaired by a Bosch dealer in the city some 60 km away and re-installed and the trip continued.

252.903 km Clutch broken: The noise we had all the time when driving up a mountain (ticking at the speed of the wheel turning) became worse. It was now also there when going down the mountain and then sometimes disappeared again. In La Paz (Baha California) there is a VW van specialist. We went to their workshop only to hear that they did not know much about the T4 only the much older T3 and T2 models. We had to come back at 16:00 hrs and they would have a look. We drove a bit with the mechanic next to us to let him hear the noise. At one point I stepped on the clutch and let it lose again and the whole camper stopped. We had to be towed back to the garage. I was still convinced it was the CV joint. Over the next 2 days they removed both joints but found nothing wrong. Conclusion it must be the coupling. Everything was put back together again and the camper was transported to another workshop (the VW specialist is very busy and did not want to spend his limited mechanical manpower on such a time consuming job). The other garage has more room (At the VW specialist the camper did not fit through the door so the tires were replaced by smaller ones). After 2 days of intense work the gearbox/coupling unit was removed from the engine and the problem became clear. The ring in the center of the clutch plate was broken off the clutch plate so that it was spinning and no torque was transferred to the gearbox. We ordered a new part from our garage in Holland and are now waiting it to arrive (8 days already).

247.460 km Right rear brake stuck When leaving a petrol station we noticed a different noise. We could not identify the source but later in the day when we drove up the mountain at the Colorado National Monument the noise changed to a scraping sound and it was clearly a brake. I checked the temperature of all the brakes and noticed that the right rear brake was very hot. We found a garage which was open on Saturday and they took the brake off. It was the hydraulic cylinder in the brake pad which was stuck. He freed it and replaced one of the 2 brake pads on the caliper which was totally worn down.

221.647 km Drive shaft removal. Already in Holland before we departed the camper was shacking a bit when driven faster than 100 km/hr. The garage could not find the problem and said it must be the off-road tiers. All the way driving through Canada the car was slightly vibrating at high speed. We did not drive quicker then 90 km/hr to keep the vibration down. At the garage in Edmonton the mechanic saw that one of the brackets holding the driveshaft up had broken. He offered to weld. Once on the road again we heard a bang and one of the bolts he had put in was pushed out. I started to wonder why the mechanic had not searched for the reason why the bracket had broken. We inserted another bolt which reduced the vibration but in the end we had to remove the axel in Fort Nelson after a further 7.200 km (228.854 km). When removing the front and rear section of the driveshaft it was found that one of the 3 bolts conn4ecting the axel via the rubber Hardyschibe to the engine was missing. That unbalance was the cause of the vibration. Was this bolt missing from the start when the axel was refurbished in Holland? The rest of the trip was driving front wheel only. The roads were good enough (even to Prudhoe bay) so we did not miss it.

221.647 km Aircon stopped working. While near Niagara Falls there was smoke and burnt rubber smell from underneath the bonnet when switching on the aircon. After that the aircon did not work anymore. We had it checked at a VW dealer in Edmonton some 4000 km further. Although it was not clear what the problem was it was determined that the electrical circuits were OK so the problem was internal in the aircon unit. We asked out garage in Assen to send a new unit. It was holiday time in Holland and we were not really in a hurry. As a result the unit only arrived some 70 days and 20.500 km later and was installed in Vancouver (242.106 km)

215.043 km Engine and Wheel mount. In Iceland we had noise which we thought came from the front drive shaft. The garage traced it back to the engine mount as well as the front wheel mounting arms. The engine shifted slightly when applying torque to go up a mountain. Both these were replaced. The wheel arms rubber were difficult to replace because the rubber, aluminum and steel joints were corroded together.

214.832 km Seikel Shock absorber failed again. All 4 shock absorbers were replaced at 179.387 km in Argentina. After that we drove to Cartagena mainly over surfaced roads and shipped the camper back to the Netherlands again for repair to the drive system (see below). We made a trip though Wales (2019) and Iceland (2021 with off-road driving). On return from Iceland, it was found that the rear left shock absorber was leaking. That was already after 35.000 km or 3,4 years. All in all I am not happy with the Seikel modified Bildstein shock absorbers. Of the 11 shock absorbers installed to date only the 2 front ones with 35.000 km are still in use. The others failed after 34,000, 41,000, 55.000, 57.000 and 76.000 km.

214.832 km Rubbers in front wheel arms are worn resulting in banging noises on the washboard roads in central Iceland. It was very difficult to remove due to fusion off aluminum tubes onto the metal bolts. A-symmetric adjusting bolts no longer available but obtained from secondhand parts dealer.

214.832 km Leaking exhaust pipe. Replaced and also installed a Catalysator which was removed for the South America trip to increase engine power.

207.160 km Unfortunately replacing the engine mount was not the complete solution. The noise came back after 280 km. This time the garage replaced both engine side CV joints. These were the joints installed in South America (see 191.506 km and 187.660 km). Fortunately I had still 2 CV joints left over which could be installed. When dismantling it became apparent that the joints did not have much grease in the cups. The joist velt a bit wobbly according to the mechanic. I thought they had to be wobbly to transfer the rotation in any direction. Maybe when heating up during driving the metal balls start rolling in the cage without sufficient lubrication and make noise and wear out. Time will tell. I hope that I can finally put this problem to rest. We are about to make a 1 week trip to test it out.

207.000 km A similar noise as experienced on our Wales trip came back. Each time after some 50 km you started to hear a clicking sound on the from left. The sound was increased when pulling up. On am left turn it was also more noticeable. First it was though to be the left tire CV joint. Later the left where bearing. Both of these were however reasonably replaced. Further investigation suggested it was the engine mount which was wobbly. ie when applying torque the engine started to tilt. The rubbers were worn out. The mount was replaced.

206.650 km New rear disk breaks and rubbers were installed. Also the electro motor of the front lock was replaced. The repair of the electronic temperature and fuel consumption display could however not be repaired (obsolete).

206.400 km When the clutch was removed it became apparent that the driveshaft to the rear-wheels needed to be overhauled. The CV joints were gone as well as the 2 Hardischibe which connect to the gearbox on one side and the Visco coupling on the other side. Unfortunately the visco coupling was not removed for testing. There is now a visco fluid available that locks at a lower temperature (ie quicker). On the other hand the specialist mentioned that the visco couplings on the T4 have a long life. Up till now I have not been able to really test at which point the 4×4 engages.

200.000 km Camper overhall in The Netherlands. PP2 was shipped back to Holland from Cartagena (Colombia) and spent some 2 weeks in the garage for repair. The tires were replaced as well as the dynamo and the rear wheel bearings. These were installed in Argentina on the first trip and may have been of poor quality. The turbo system was checked, and new sensors were installed. Now the power is back. On the first long drive through Wales (UK) this summer we discovered that the right-side CV joint was making a terrible noise. Some rings were missing, so a new CV was installed. In January the clutch will be overhauled again, and a new flywheel installed. The camper should then be good for shipping to Halifax, Canada, for part 3 of our 4-part America’s trip (Prudobay to New Orleans).

194.220 km The left rear break started to make a scratching sound. In the garage it appeared that besides worn break pads also one of the cylinder rods on the left side was broken. That resulted in one pad being totally warn while the other had still some body left. Fortunately this break specialis know what they were doing and good get hold of all the parts.

193.632 km Flat tire The turbo really does not give much power anymore. You have to climb the hills in second and sometimes first gear. Due to the engine noise we did not notice that the left rear tire was flat. A friendly bypass pointed it out. We stopped at a nearby tire place and replaced both rear tires with the ones we had bought in Argentina.

193.317 km Break clam dropped Ever since the repair in Lima we had a noise up front. We could never identified the problem. However after some 1800 km the noise increased and the right front brake squeaked. After removing the right wheel I noticed that the break clamp was lose. The top bolt had dropped out and the lower bolt was loose. It was most likely never tightened after the clutch over hall in Lima. I got a lift to the nearby town, but there they had not the right bolt size. I took the bus back to Loja (70 km) and with the help of a taxi driver found the bolt. With the help of the GPS the return bus stopped at the camper and the bolts were put back in place (and tightened!).

192.633 km Dynamo issues While driving we noticed the voltage goes up and down. I first directly connected the rear battery (camper) to the front battery (car) assuming that the relais switch was broken. Later it became clear that now both batteries were being drained since we had the headlights on and that the dynamo was not delivering power. I disconnected the car battery totally from the camper battery. Now the rear was charging again by the sun panel. However power was fluctuating so there was a loose contact. This was located and fixed. We parked the car and the next morning the car battery was flat. With cables we got the car started again but after 5 km everything went dead. The diesel pump also got no power. We flagged down a friendly Peruvian (Pedro) who towed the camper to a small closed in parking lot. Over night the car battery was charged and without assistance the car started in the morning and we drove to a mechanic. He checked the dynamo and cleaned the contacts. Since then it delivers power and also is charging the camper battery again.

191.506 km Clutch failureIn the traffic jam driving out of Lima I noticed that the clutch did not disengage completely. More and more I had to break the car in order not to bump against the car in front. At one point all the clutch backpressure was gone and I was full on the brake. Smoke started to appear so we crossed all the (clogged up) lanes and parked at the nearest garage. The brake/clutch fluid reservoir was empty. After filling there still was no backpressure on the clutch and it was stuck in gear. On advice from VWstore in Assen we rocked the car a bit and got it out of gear. When running the engine the clutch pressure did not increase. Javier called up a tow truck which brought us to a garage on the outskirts of town (1 hr from our city address).

We stayed the night close to the garage in a Hotel which rented rooms by the hour. The mechanics spent 2 ½ days to remove the gearbox and clutch. As expected the high-pressure seal of the clutch pump was leaking. The clutch plate showed signs of burning but was still usable. A complete plate set and hydraulic seal was ordered from Germany and it took 5 days (incl. weekend) to arrive. Again it was weekend so only on Tuesday 5/2 after 13 days was the camper ready.

190.268 km Gearshifer became wobbly and sometimes failed to go into first/second gear.

To climb over a pass at 4725 m we had to shift gears quickly between first and second. At one point the gearstick became very wobbly and it was sometimes impossible to get the gear into first and second. The gearshifter has 2 teflon balls. One of them is pressed into a Teflon holder. This ball was stripped out and the holder was broken. As a result changing into lower gears became difficult. At a garage in Cusco the broken holder was removed and after several prototypes a suitable one was made and inserted The Teflon ball was pushed back into place. A repair set costs only $8 and was ordered from Germany and sent to Lima. Once we get to Lima from Cusco we will have to see if we replace the provisional one.

187.660 Left CV joint on the motor side failed.

The bolts must have come loose during the previous day washboard road. 2 bearings were found when the carter protection was removed along the road. In a garage the whole drive axel was removed.

We continued driving with only 1 front wheel drive but still 2 rear wheel derives albeit at 30 %. New parts were ordered from Europe and sent to Lima. We drove in the mean time some 1800 km on till Puerto Maldonado in Peru to wait for the parts. Because of the Christmas vacation the ordering alone took 5 days. The CV joints were ordered at 2 different shops. The German one with DHL arrived in Lima on 31 December and in Puerto Maldonado on January 3. The Lithuanian one only arrived on xx January via UPS. Again the holiday did not help. A local garage put the axel back together again and installed it under the camperin just over 3 hrs.

182.553 Power breaking system failure

The break power was severely reduced. After some 760 km we stopped at VW garage. There they discovered that the vacuum hose connection to the power break was not connected. After reconnecting and securing the connection all was well again.

181.000 km Turbo failure.

When driving the turbo suddenly stopped working. One time at high revs it worked again but after stopping at a garage it would not start again. We crawled up the hills to the nearest city at the border. After visiting several garages both in Paraguay and Brazil we ended up at the VW garage in Foz do Iguacu. The computer indicated an electric problem. After repairing the wire we went on a test drive but it was clear that there still was no turbo power. The turbo was completely removed from the car and brought to some specialists. They could not find any fault.

Subsequently the air system was removed. That showed that the large air filter was sucked into the pipe. So the turbo works but did not get air.

Airfilter, possibly wet and sucked in

The other valves all seemed to work. The ERG valve had one of its ports closed off with a metal plate. There was a small hole eroded in it. The VWstore in NL suggested that this was part of the chiptuning and should be left as is.

All was built back into the camper.

This time the test drive was more successful!. The tuning had to be set back to factory setting so we will miss the extra boost of the chiptuning. The whole process took some 8 days. If we would have to get a new turbo from Europe it would have taken at least 2 weeks.

So all in all not too bad. Hopefully it will not fail again. It was helpful that the manager of the garage and his nephew spook English. They could explain what was being done. Because the turbo was set back to original conditions the power of the engine has reduced by 20 – 30 %. You really feel this along the way. On a climb you sometimes cannot overtake trucks!

179.523 km Repair of shock absorbers, springs etc in Buenos Aires.

We bought 4 new shock absorbers as well as 2 new springs in Holland. They were succesfully installen in Argentina beginning November 2018. At the same time new stabalisation arms as well as steering arms were installed and to top off the front bearings were replaced. The camper now drives a lot better.

177.529 km: Rear left spring coil broken. Removed noisy broken off part and drove on.

177.432 km: Three beep noise and warning light flashing. Misinterpreted the alarm and added cooling fluid. Alarm continued. Shortage of brake fluid. Filled at earliest opportunity (160 km) after first buying the wrong type of fluid.

176.817 km: Rear left shock absorber stripped out again. Noticed no more shock absorbing power. Manually pressed it back in place and installed a new bolt.

176.357 km: Second time the tire rack came loose from the camper. This time cut a new thread into the bolt inside the camper wall and screwed in a larger bolt together with locktight.

175.567 km: Tire rack came loose from camper. 1 bolt could not be tightened any more. The glue was slowly letting loose and the whole construction could tear off. Screwed in a new bolt and added some 2 component glue (this did not hold). Also in Las Varillas had the frame welded again since one bracket weld was broken.

175.567 km: Right rear shock absorber stripped out of the nut. Made new tread over old tread and inserted a new bolt and rubber.

174.688 km: Started to notice noise in the rear drive system. When speeding up to over 90 km/hr the noise reduced. In La Paz had it diagnosed at the VW garage. They suggested it was driveshaft vibration. It was safe to drive on till Cordoba (2000+ km). In Las Varillas (near Cordoba) had it re-diagnosed as the right rear wheel bearing. With great effort removed and replaced the wheel bearing on both the rear wheels.

173.946 km: Front right torsion bar connection broke off again. Drove down the mountains to Arica (250 km) and had it welded again.

171.368 km: Front left stabilization bar broke off. Slowly drove over a 2000 m mountain path to a truck welding shop (65 km). Within an hour they had the connecting ball joint welded back on to the stem and we could drive on.

169.523 km: Pipe of the main silencer under the middle of the car broke off (rust) and it was banging against the driveshaft. In a small town a welder was found who welded it back together again.

166.876 km: Left rear shock absorber stripped off the bolt and banged up and down when going over bumps. Reinstalled rubbers and welded/treaded a new bolt to the pin of the shock absorber.

166.876 km: Front right stabilization bar broke off. Bend away from driving shaft so we could drive to a garage (200 km). In garage welded a new connection together made up of the old one and a new one. The ones available had a different thread (American) and were longer.

166.655 km: During replacement of the front left shock absorber, discovered that the front driveshaft rubber was torn. Fixed by removing the driveshaft (very time consuming) and installing a new rubber.

166.381 km: Left front shock absorber leaked after driving over a very bumpy road with some deep ruts. Drove on and replaced in Coyhaique.

166.087 km: Handbrake cable came loose. Pulled/tightened back into place.

165.086 km: One rear tire was leaking and the other was worn to the steel tread after 72.000 km. Installed both spare Goodridge tires and bought 2 new Argentinean tires as spare.

Interior

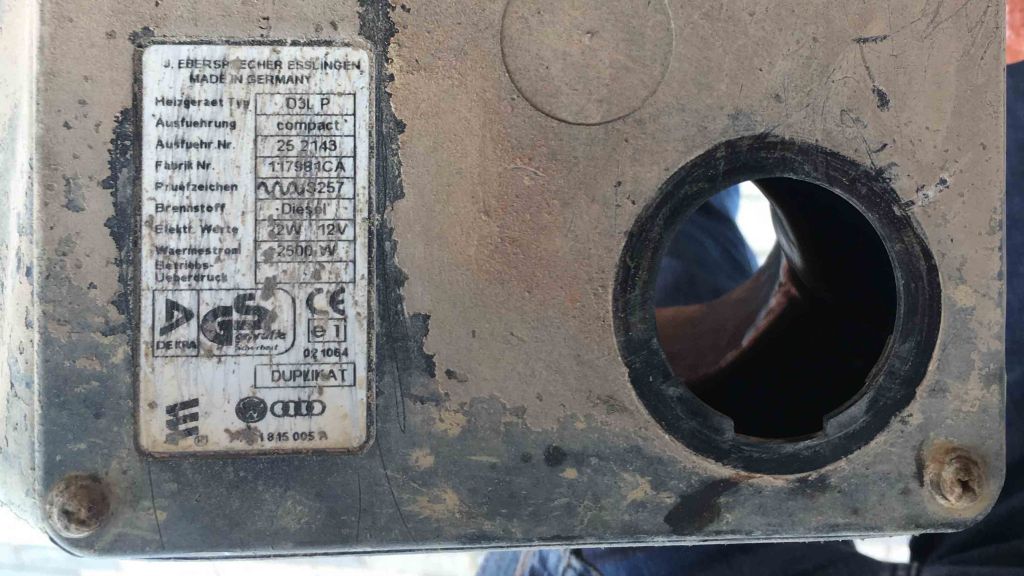

1/10/2021 Standkachel

Mijn standkachel is nu gerepareerd. Hij is stuk gegaan bij het doorwaden van te diepe rivieren in IJsland. Daardoor is niet alleen de elektronica stuk gegaan maar ook de ventilator. Hij kon maar met moeite met de hand worden omgedraaid.

Ik ben eerst bij een Eberspacher dealer in Groningen langs geweest. Die gaf aan dat reparatie niet meer mogelijk was. Bovendien zijn de onderdelen niet meer te krijgen. Deze onderzoek kosten had ik mezelf kunnen besparen want hij bevestigde alleen maar wat ik al verwachte.

Via Pieter en Weetjewel ben ik toen in contact gekomen met Oskar ( oskari@xs4all.nl). Hij reviseert standkachels. Bij hem thuis in Asperen heeft hij mijn kachel er onderuit gehaald en getest. Ook een andere unit die ik op marktplaats had gekocht heeft hij getest. Beiden functioneerde niet meer. Gelukkig had hij nog een compleet gereviseerde unit. Die werd getest en is onder de camper geplaatst. De elektronische print plaat, die de kachel aan stuurt en communiceert met het dashboard boven de achteruitrij spiegel, is moeilijk te krijgen. Ik had er drie maar ze waren allen stuk.

Helaas deed mijn kachel het niet als hij werd aangestuurd via het dashboard in de camper. Deze heb ik voor schoonmaak en doormeten gestuurd naar Henk (henk@hrwerkplaats.nl) in Amsterdam.

Het was even spannend toen alles geïnstalleerd was en ik op de dashboard knop drukte. Als de kachel namelijk in foutmode gaat dan kun je die, zonder een speciale controle unit, er niet uit halen. Gelukkig ging alles tegelijk goed. Eind goed al goed (maar wel kostbaar, €750 voor de revisie unit en dan nog alle andere kosten). Dus maar niet meer door te diepe rivieren rijden.

30/10/2020 In order to get more ventilation during the night we replaced the tilting window for a sliding window. A metal mosquito guard can be put in. In this way Jamaliah feels safer when leaving the wind open.

28/6/2019 The roof vent was replaced by a maxxfan. Now the cooking smell are vented out and at night there should be more ventilation for Jamaliah, who sleeps on the lower bed.

- Connection of water basin drain broke and water was leaking when draining the basin. Solution wrapped some tape around it. This was repaired with 2 componet glue in November 2018. In order to get to the connection we accidentaly pulled out the drain pipe. With some delicate fishing we got it back in place.

- When overfilling the water tank the water spills over. The seal of the tank no longer is water tight. Solution; Observe water level in tank when filling and do not overfill.

- Bed plank could not be pulled out. A screw came loose and had to be tightened.

- Handles on sliding cupboards came loose. The screws had to be tightened again.

- Household battery is not charged when the car is driving. Dynamo does produce 14.3 V when no power is required however when driving the voltage drops to 12.8 or even down to 12.4 when climbing. This is not enough to charge the Gel Battery. Most likely the dynamo does not give enough current. (expected 40 – 60 amps at 2000 rpm, measured only 20 amps). Most likely the dynamo regulator has an issue. Still to be resolved. In November 2018 we installed 2 new batteries. Still the problem was not solved. In Montevideo we had the altenator checked but that was also OK. In the end an eath wire was pulled from the front batterie to the rear. That solved the problem. The camper batterie is now properly charging.

Pffff, after reading this list, I am surprised you ever reached Cordoba! 🎂☺

LikeLike

sounds like you have given the suspension system a good bashing. success on your ongoing travels.

Hans

LikeLike

Is er een verklaring te geven voor al deze malheur? Ik vind het voor een T4 niet normaal om 16 keer naar een garage te moeten tijdens een reis van 12.000 km.

LikeLike

Ik ben het met je eens. Ik denk dat ik te veel gewicht op de achter as had (ie Reserve wielen @70 kg en op de bagagedrager 40 kg aan fietsen incl drager). Ook ben ik te hard door een paar diepe kuilen gegaan bij Chili Chico. Toen zijn de problemen begonnen. Dus als een onderdeel kappot gaat (ie de schokbreker rechts voor) dan kunnen de andere onderdelen het niet meer aan en gaan ook een voor een kappot. Ik neem nu 30kg aan schokbrekers, veren en lagers mee terug naar B.A. Hopelijk op de volgende deel van de reis zijn er dan minder problemen.

LikeLike

And Passepartout is back on the road again. Well done guys. All you have to replace is the front windshield and you’ll have a new car. Stay save and thanks for all the stories and the beautiful pictures.

LikeLike